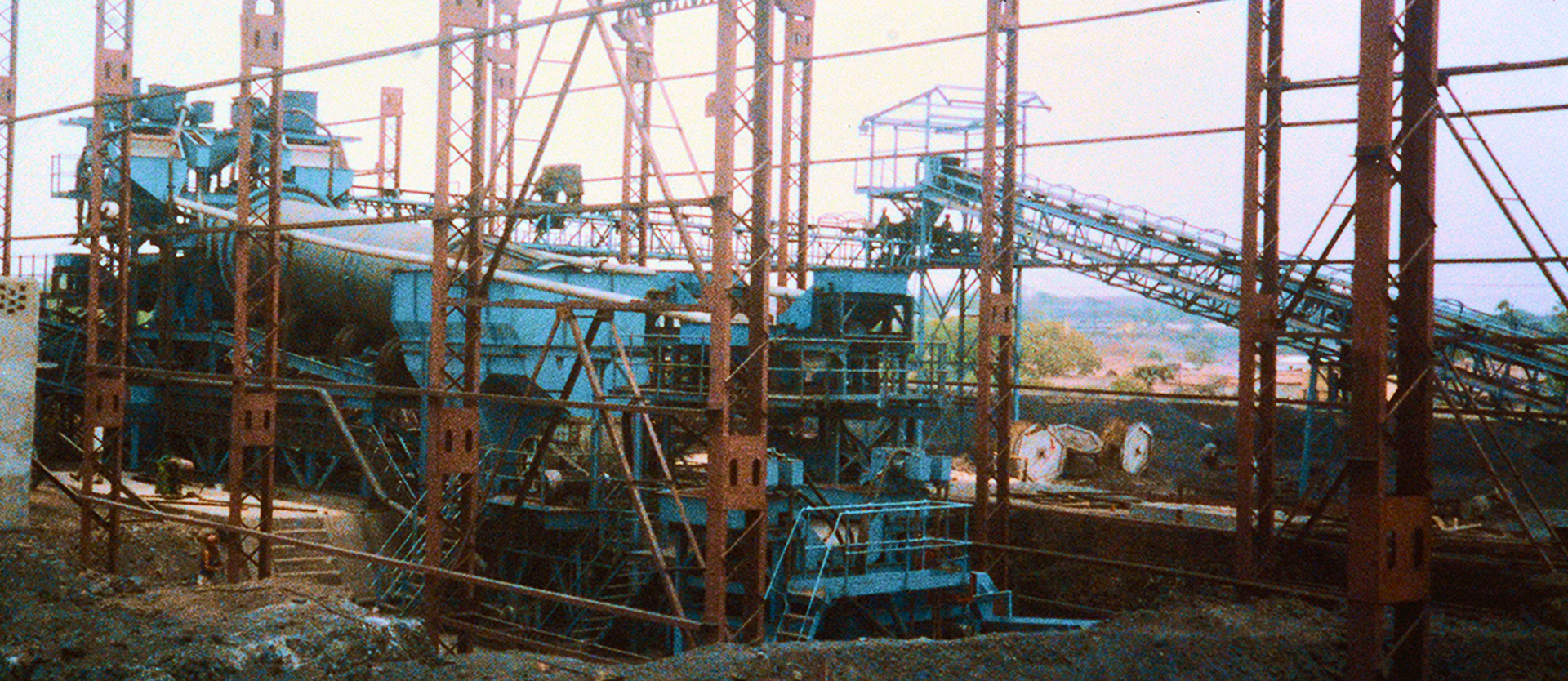

Coal Washery

WHERE ENGINEERING MEETS SUSTAINABILITY

CRSPL enhances coal quality through advanced wet washery technology, reducing impurities at the source to cut transportation costs. Their expertise spans coal, manganese ore, and limestone washing, ensuring efficient and eco-friendly processing.

About Coal Washery

CRSPL specializes in coal washery services, which involve the process of removing impurities and contaminants from raw coal to enhance its quality and purity.

Coal washery facilities use a combination of techniques such as screening, washing, crushing, and gravity separation to separate coal from its impurities like rocks, soil, and other foreign materials.

CRSPL uses a wet technology operating with self-generated slurry as media. In collaboration with a British firm, the technology was first incorporated at a mine at Dhanbad, under the S&T Grant from the Govt. of India and it proved to be successful.

CRSPL has shown the way of a Pithead Washery capable of washing coal at the mine end and leave the dirt behind and save transportation of ashes laden in coal.

We at CRSPL deal in the following :

Coal Washing Plant

Manganese Ore Washing Plant

Limestone Washing Plant

Coal Washing Plant

Natural plant medium consisting of coal fines generated in washing unit has been found to be the most cost effective in processing and separating ash in ROM coal. The coal fines are generated from the ROM feed coal. These natural medium washing units are most cost effective method, processing ROM coal for industrial use.

The technology is backed by a British process design. The first plant of this technology was implemented under Science & Technology (S&T) Grant, in Lodna Colliery, BCCL, Dhanbad, through CMPDIL, Ranchi, in 1991, on subjection of stringent performance test of difficult coal of Jharia coalfield. Performance through test was found satisfactory. Subsequently, a number of plants on this technology were built and found fully successful for both coking and non-coking coal.

CRSPL's Combined Natural Media & Dense Media Washing Plant is designed for high-efficiency coal purification, achieving 95-96% organic efficiency while handling diverse coal inputs. Utilizing four separation functions—Barrel, Cyclone, Dewatering Screen, and Sieve Bend—it enhances calorific value and reduces ash and sulfur content. With a robust modular design, the plant offers low capital expenditure, quick assembly, minimal manpower, and reduced pollution, ensuring low power and water consumption while maintaining high efficiency and cost-effectiveness.

Elevating Possibilities, Connecting Destinations

Revolutionizing ropeway and material handling solutions with cutting-edge technology and decades of expertise. From urban transport to industrial logistics, we engineer seamless, sustainable, and efficient systems that redefine connectivity.

Types of Plants Offered

A. Barrel-cum-Cyclone Plant

Capacity Range : 25-300 TPH

This type of plant is ideally suited for reducing ash in low grade coal for the following :

-

Power Sector

-

Sponge Iron Units

-

Cement Plants

B. Barrel Only Washing Plant

Capacity Range : 25-300 TPH

This type of plant is capable of handling high extraneous ash, reduction of which can be in the region of 10-12%.

C. Cyclone Only Plant

Capacity Range : 15-30 TPH

The design is simple and involves low investment, which is the USP. This is particularly suited for small consumers like :

-

Cookeries

-

Small size Sponge Iron Plant

D. Slurry Treatment Plant

Capacity Range : 10-15 TPH

This type of plant is ideally suited for reducing ash in low grade coal for the following :

-

Power Sector

-

Sponge Iron Units

-

Cement Plans